A few decades ago, Japan Inc. supplied almost 90% of the world’s memory chips, and just over 50% of the entire semiconductor market. Trade tensions flared between the US and Europe. The industry shifted, moving to processors and chip designers who outsourced to manufacturing foundries, most in Taiwan and South Korea.

Today, Japan is back, reinventing itself as a vital semiconductor global player. From critical minerals and chemicals to lithography and semiconductor equipment, the country has charted a path to reduce supply risks. The success shows how smart policy can neuter China’s potential stranglehold. As a reliable ally, Japan will play a key role in the just announced US Pax Silica project designed to reinforce the “silicon supply chain — from critical minerals and energy inputs to advanced manufacturing, semiconductors, AI infrastructure, and logistics.”

The initial spark came in 2010, when China imposed a rare earth export embargo on Japan amid a diplomatic spat, revealing the risks of overreliance on a single supplier for essential materials. At that time, Japan depended on China for up to 90% of its rare earth elements — critical not only for semiconductors, but also electronics and automobiles.

Japanese policymakers, manufacturers (such as Toyota and Sony), and government agencies launched a nationwide effort to “de-risk.” It partnered with Australia’s Lynas Rare Earths, the largest non-China producer, and expanded a processing plant in Malaysia. By 2025, Japan had cut its dependence on Chinese rare earths to around 60%.

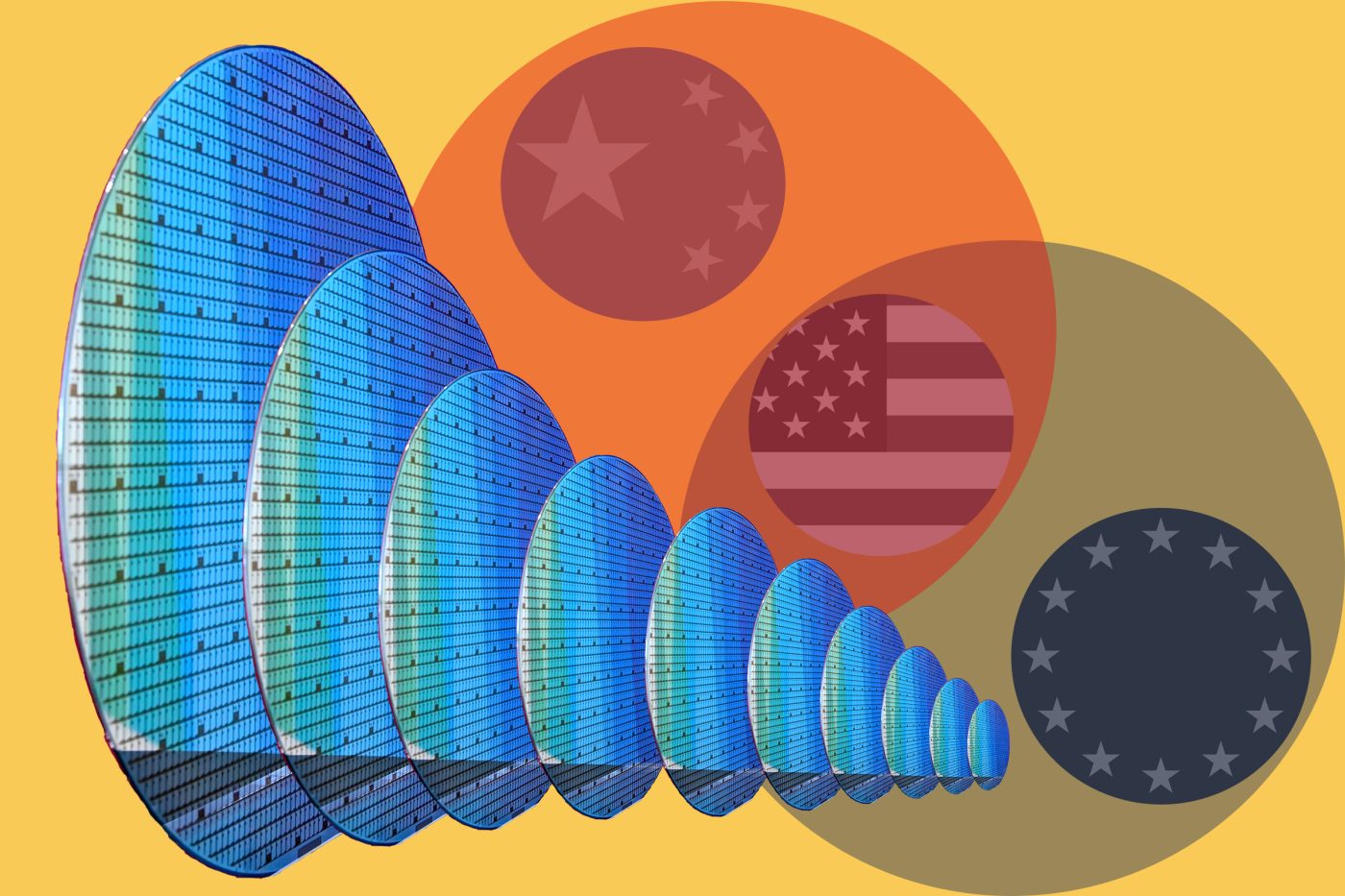

This 15-year sustained effort shows how Tokyo mobilizes for the long term. In parallel with reinforcing foreign supplies, Japanese companies JSR, Shin-Etsu, and Tokuyama dominate the chemicals needed in EUV (extreme ultraviolet) lithography machines needed to etch silicon chips. Japan is also strong in silicon wafer manufacturing, with Shin-Etsu Chemical and SUMCO among the world’s largest suppliers.

This chemical chokepoint is powerful. In 2019, Japan imposed export restrictions on these chemicals to South Korea during a bilateral dispute.

But Japan most often prefers working with, not against, allies. It has imposed export controls to limit China’s access to advanced chipmaking supplies, and has signed semiconductor partnership agreements with countries around the globe, including the US, Vietnam, and India.

Partners are key to boosting domestic chip production. The government has spent billions to convince Taiwan’s TSMC to build a giant new fab on farmland in Kikuyo in southwestern Japan. It opened last February, and a second plant is now planned.

Japan’s biggest chip bet is Rapidus, a startup founded in 2022. Backed by the government and corporate heavyweights like Toyota, Sony, and SoftBank, Rapidus is constructing a fab on the northern island of Hokkaido. It is successfully prototyping a 2nm gate-all-around transistor in partnership with IBM — a tangible step toward reclaiming advanced manufacturing leadership. If this high-stakes gamble pays off, Japan’s “Island of Flowers” could become the Pacific’s next Silicon Valley.

Japan is already a world leader in lithography and semiconductor equipment, controlling around 30% of the global manufacturing equipment market with key Japanese companies like Tokyo Electron, Nikon, and Canon.

Behind the chipmakers stand Japan’s electronics giants — including Sony, Panasonic, and Toshiba. Sony is a global leader in image sensors, while Panasonic has advanced expertise in automotive and industrial chips, often partnering with other national and global players for R&D and production.

While Japan’s industry is strong in key “front-end” (wafer production) and “back-end” (assembly, testing, packaging) steps, it also continues to excel in core materials and chemicals, further anchoring its role in the global supply web.

Despite current advances, challenges remain: Japan must secure more than $32 billion in capital for scaling up production and faces a critical shortage of highly trained semiconductor engineers. Historic issues — such as fragmented industry structure and slow adaptation to industry consolidation — limit Japanese leadership in cutting-edge AI chips.

Both the US and Europe should see Japan as an essential and trusted ally for securing the future of global semiconductor supply chains. Japan’s unmatched capabilities across the value chain, deep-rooted collaborations with American and European technology leaders, and proven reliability stand in direct opposition to the competitive and geopolitical risks posed by China.

Christopher Cytera CEng MIET is a Senior Fellow with the Tech Policy Program at the Center for European Policy Analysis and a technology business executive with over 30 years’ experience in semiconductors, electronics, communications, video, and imaging.

Bandwidth is CEPA’s online journal dedicated to advancing transatlantic cooperation on tech policy. All opinions expressed on Bandwidth are those of the author alone and may not represent those of the institutions they represent or the Center for European Policy Analysis. CEPA maintains a strict intellectual independence policy across all its projects and publications.

2025 CEPA Forum Tech & Security Conference

Explore the latest from the conference.